dave_7, CC-BY-2.0 via Wikimedia Commons Systems engineering builds on that interconnectedness. Not only do parts in a system work together, but if one of them is exposed to a certain condition, it will affect the other pieces as well. This is vital for larger projects and ties nicely into the multidisciplinary aspects of systems engineering. If one of these parts is made of a less-than-ideal material, it can break. This in turn affects the other pieces, and thus the integrity of the system at large is compromised.

Interconnectedness in My Team’s Moon Rover Design

Systems engineering is a rapidly growing field, especially when it comes to aerospace applications. I was lucky enough to participate in a NASA competition at Drexel, in which my team and I designed a rover that would explore the poles of the moon to look for ice. In these areas, the temperatures would be incredibly low, and this would affect the robot in many ways. Working on mobility, my top priorities were movement and navigation, or how to get over or around obstacles and how to tell where the robot was going. However, a typical robot design would not work here, as the temperatures prevent most motors from functioning, and without proper insulation, the power supply would deplete as well. This impacted our design in terms of the material of the wheels, motor placement, and overall function. The motors could not be placed at each wheel, as that would require more insulation over larger areas, taking up precious space and adding weight. This would have also required wires running the length of the vehicle, which would also have been affected by the extreme temperatures. With this in mind, we had to design the robot to be a rear-wheel drive design, with the power supply and motors located in the back of the rover and a single axle that would control how the front wheels turned. This minimized weight, our area of insulation, and the number of motors we needed. Unfortunately, this came at the cost of power to our front wheels, but this was something we accepted in our list of priorities. This is an example of how the properties and design affected the rover’s capabilities. Another great example is the lunar dust, regolith. Regolith is very fine dust that holds a slight electric charge. This charge attracts it to metal, and it can get everywhere inside a rover. If it got into the joints of the robot, it would be catastrophic and could prevent actions as basic as turning. While we designed most of the robot out of non-metal materials to prevent this, there were certain areas in which we could not sacrifice strength for a non-metal material. To counter this, we planned on including something that would produce a weak electric field to repelll the smallest particles and keep the rest of the rover safe. This required an extra layer of protection to be added for the on-board electronics, but we decided that this would work best overall.

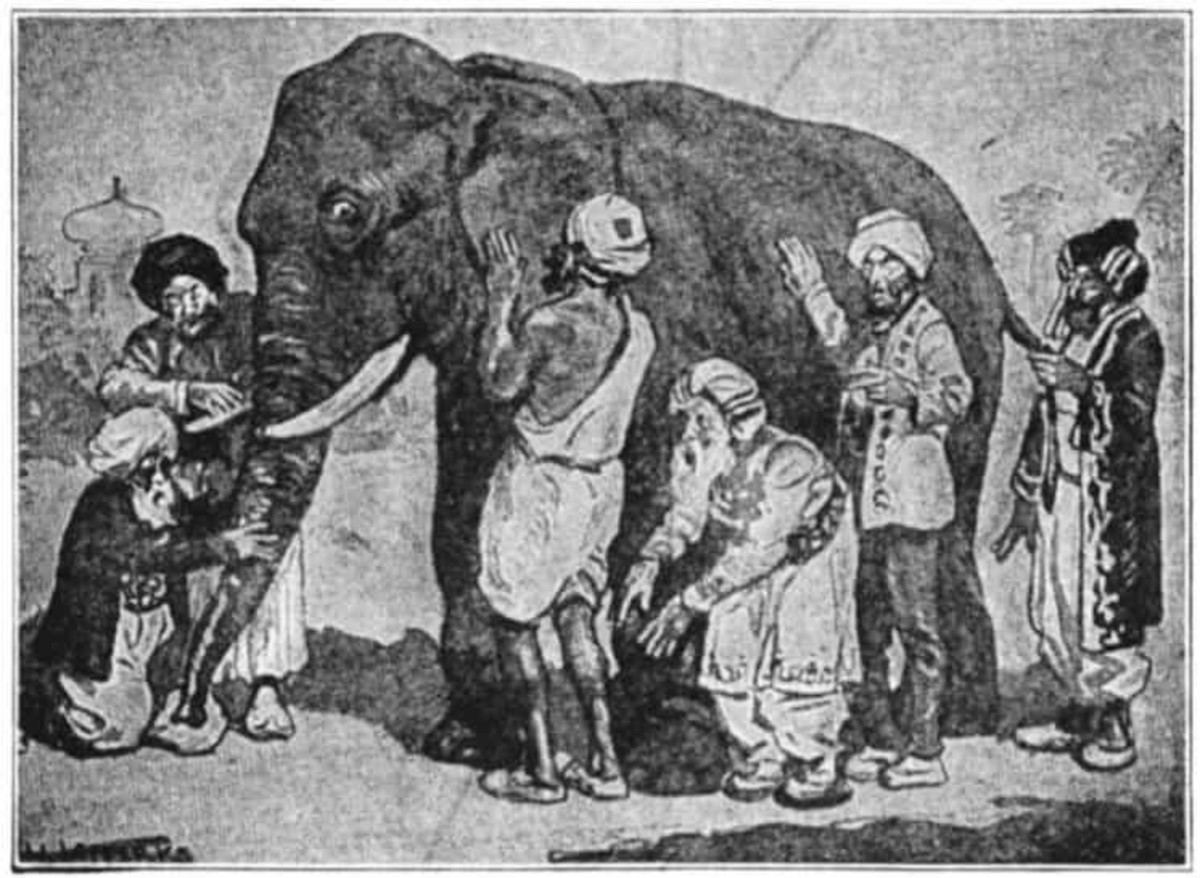

Looking at the “Whole Elephant”

A common parable to detail this interconnectedness is the story of the llind men and the elephant. The parable goes something like this. A group of blind men encounters an elephant for the first time. The first man feels its winding trunk and claims to be touching a snake. The second touches a sturdy leg and claims that it’s a tree. The third feels its solid side and believes they are touching a wall. The fourth grabs the tail and thinks it is a branch. Another feels the tusk and believes it is a spear, while the last one grabs the elephant’s ear and tells the others that it is a fan. The overall point of the story is that in order to view the whole of a system, one must look at all of its components and how they fit together. Especially when it comes to space exploration, projects require engineers to look at the “whole elephant.” In the article “Seeing the ‘Whole Elephant’—Systems Thinking in Evaluation,” Srikanth Gopal, the author, claims that the field of evaluation has traditionally been led by a reductionist view. In an attempt to simplify complex systems, engineers are typically required to look at a single, small factor to make it the best it can be. However, this sometimes ignores how pieces work together, even when they aren’t directly attached. For a successful rover, even something as simple as the wheels must be designed with regard to nearly everything else on the rover, such as weight distribution, extending parts, insulation, and more. It even has to take into account external factors such as the terrain and travel distance. How each component of the robot works with each other (i.e., how the parts is interconnected) is the deciding factor between success and failure.